Predictive maintenance has become a strategic pillar for modern industry, especially in OT environments (Operational Technology), where availability and system reliability are critical. This strategy aims to anticipate failures before they occur, through continuous monitoring and intelligent analysis of operational data. However, for predictive maintenance to be truly effective in a connected industrial environment, it must also incorporate a cybersecurity dimension.

This is where InprOTech Guardian comes into play — a platform designed to protect OT environments that also provides the capabilities needed to take predictive maintenance to the next level.

How does Guardian contribute to predictive maintenance?

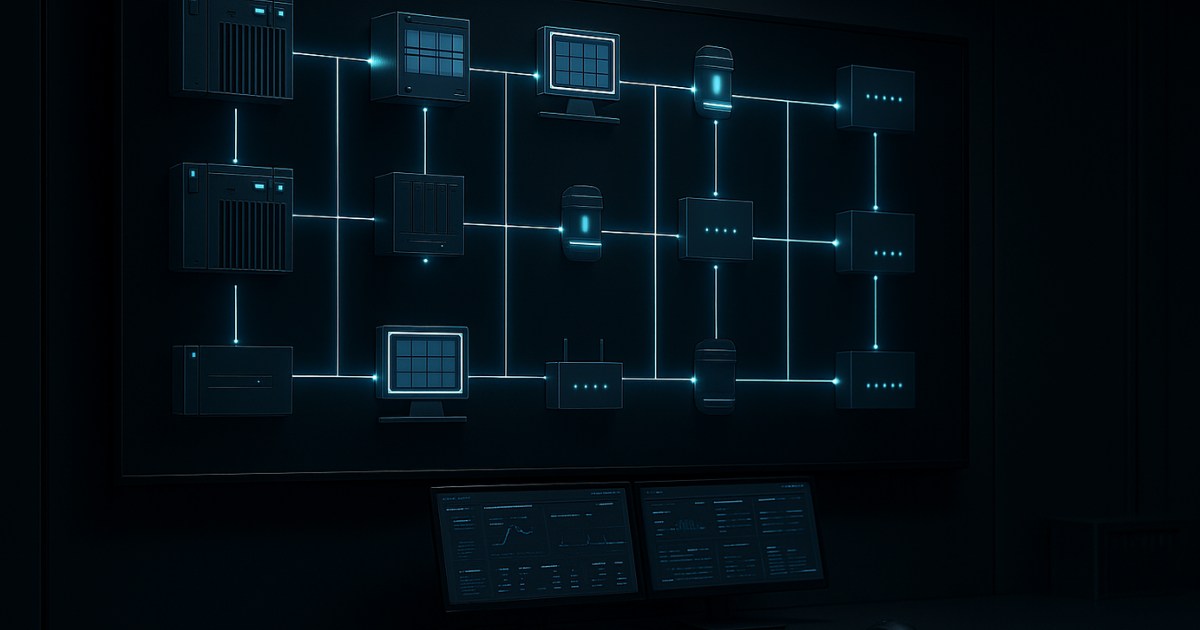

Asset discovery and dynamic network mapping

Guardian enables the creation of a live and accurate inventory of all devices present in the network, including: PLCs, SCADAs, industrial routers, sensors, wireless and unauthorized devices. It automatically classifies them by Purdue level, manufacturer, firmware, and criticality. This allows to prioritize maintenance tasks and detect suspicious changes.

Monitoring industrial traffic as a diagnostic source

Guardian provides deep packet inspection of OT traffic (DPI), visualizing interactions, anomalous traffic or inactive services. If a PLC stops emitting cyclic traffic or behaves abnormally, it could be a technical failure or an attack.

Analysis with AI/ML algorithms trained in OT environments

Guardian’s artificial intelligence engine identifies deviations, degradations, intermittent errors, or patterns that might go unnoticed without AI, anticipating technical failures or cyber threats.

Custom static rules for technical alerts

Guardian allows configuring specific alerts for maintenance: unauthorized writes, unexpected reboots, etc. These rules help detect anomalous conditions in a precise and automated way.

Guardian generates weekly reports with key technical information: scoring, traffic, alerts, public IPs, etc. This allows maintenance planning or proactive risk assessment.

Integration of maintenance and cybersecurity: a strategic advantage

The line between a technical failure and a security incident is increasingly blurred. Guardian helps correlate both worlds, providing technical and cybersecurity context for informed and reactive decisions.

Conclusion

Using Guardian as part of a predictive maintenance plan enables:

- Achieving full and updated visibility of industrial devices.

- Detecting anomalous behavior in advance.

- Correlating technical alerts with possible physical or cyber causes.

- Prioritizing maintenance resources according to criticality and network context.

- Increasing operational resilience against failures and attacks.

In summary, Guardian turns OT monitoring into an active source of prevention, reducing risk, improving planning, and anticipating mechanical and digital threats.